Top ski tuning tips

To make sure that the base of your ski or board is truly flat, use a ‘true bar’ or a metal scraper. Hold the edge of your true bar or scraper on the base and look to see if it is in contact right across the edge. The most common problem is that the ski is ‘railed’ – the edges are higher than the base. Use a 25cm mill file to take the edges down until the base is completely flat.

It’s all about those little grooves on the bottoms of your skis. Structuring helps a ski glide more efficiently and makes it easier to turn for greater control. According to World Cup technicians, structuring can make more difference in speed than waxing. A ski base gets increasingly fast after it is structured, to a point, then it will start to slow. You can use a brass brush to revive the structure and open the base – this will bring back the speed.

It’s all about those little grooves on the bottoms of your skis. Structuring helps a ski glide more efficiently and makes it easier to turn for greater control. According to World Cup technicians, structuring can make more difference in speed than waxing. A ski base gets increasingly fast after it is structured, to a point, then it will start to slow. You can use a brass brush to revive the structure and open the base – this will bring back the speed.

Many people like to put a small bevel on the base edge of 0.5° to 1°. This makes your skis less catchy and allows a smoother initiation of the turn. Bevel consistency is everything. Bevel from the very tip of the ski to the end of the tail, beyond the contact (where the ski touches the snow) to create an uninterrupted angle along the length of the ski. The abrasiveness of snow, especially hard snow, will increase base edge angle over time, as edge material wears away more quickly than the base. Be careful: dull files require more pressure to cut, and that pressure can create too much bevel or an uneven base bevel.

De-tune edges using a gummi stone only! This allows the edge to be brought back to sharp if needed. When you are using hand files it is important to listen and feel for a clean cutting action. A grinding noise indicates one of three problems; the file is blunt, in which case replace it; you are using the file the wrong way round in which case change it; or there may be hardened bits of the edge from hitting rocks. If this is the case use a diamond file to remove these hardened sections and then go back to your normal file. If you find that you are cutting plastic from the sidewall as well as metal then you MUST stop and use a sidewall remover before continuing.

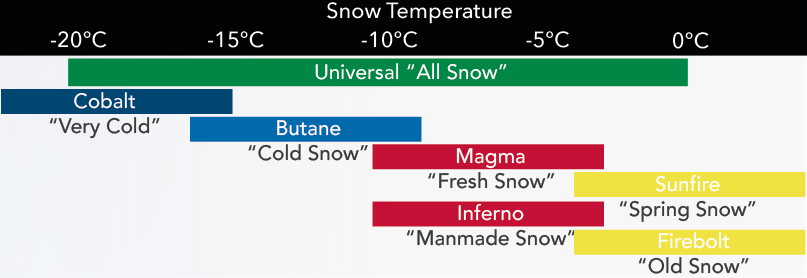

Hot scrape skis to clean. Soft hydrocarbon waxes like DataWax Magma Backcountry or Sunfire penetrate deeply into the base. Scraped while hot, this pulls out old wax and impurities and at the same time nourishes the base. Repeat until wax shavings appear clean. Finish with a brass brush. Use a snow forecast website and look for the overnight low temperature to select your wax. If unsure which wax to use always err on the colder side.