Gear read | Blizzard-Tecnica

We talk to Maurizio Priano, Head of Marketing at Blizzard-Tecnica, about the brands’ latest backcountry innovations, female focus & sustainability initiatives

Sophie Nicholson: Head of Marketing for two massive ski brands! That’s a big job Maurizio… tell us a bit more about your role and what it’s like balancing the needs of two brands simultaneously

Maurizio Priano: As Brand and Marketing Manager I’m quite lucky. I’m working with one of my passions – skiing – and I’m doing that with two of the most innovative brands on the market. My job is quite easy – I don’t need to invent any marketing stories to make our products attractive: their quality and performance, and the testimonials of mountain professionals, tell our consumers all they need to know.

Finding the strategy to make Blizzard and Tecnica coexist together, respecting their different heritage and personality, has been an interesting challenge. But, ultimately, being two specialists of their own segment, skis and ski boots, Blizzard and Tecnica are designed to work together so it’s a natural partnership.

SN: Founded in Austria by a carpenter after the second world war, Blizzard now runs the fourth largest ski factory in the world. Can you tell us which other companies you guys produce skis for?

MP: Our Blizzard home is something we are really proud off. It’s in Mittersill, a small village in the Austrian Alps, at the footsteps of one of the most impressive downhill runs, the Streif in Kitzbühel. Here, skiing is not a sport, it’s a religion, and the art of wisely combining the best technologies with innovative designs is something that is taught at school. Other brands like Nordica also take advantage from this incredible knowhow.

To find the best playgrounds, freeriders are increasingly moving away from resorts and into the backcountry

SN: From a Blizzard point of view, the biggest story for winter 2023 is the launch of the backcountry/freeride Hustle series. Tell us more about the new collection and how it came about…

MP: The search for untouched, perfect snow is endless. To find the best playgrounds, freeriders are increasingly moving away from resorts and into the backcountry. With no lifts, accessing this terrain is dependent on human power. Freeride skis are often too heavy to skin up for long periods, while lightweight ski touring skis often lack the playful performance that freeriders seek for the descent.

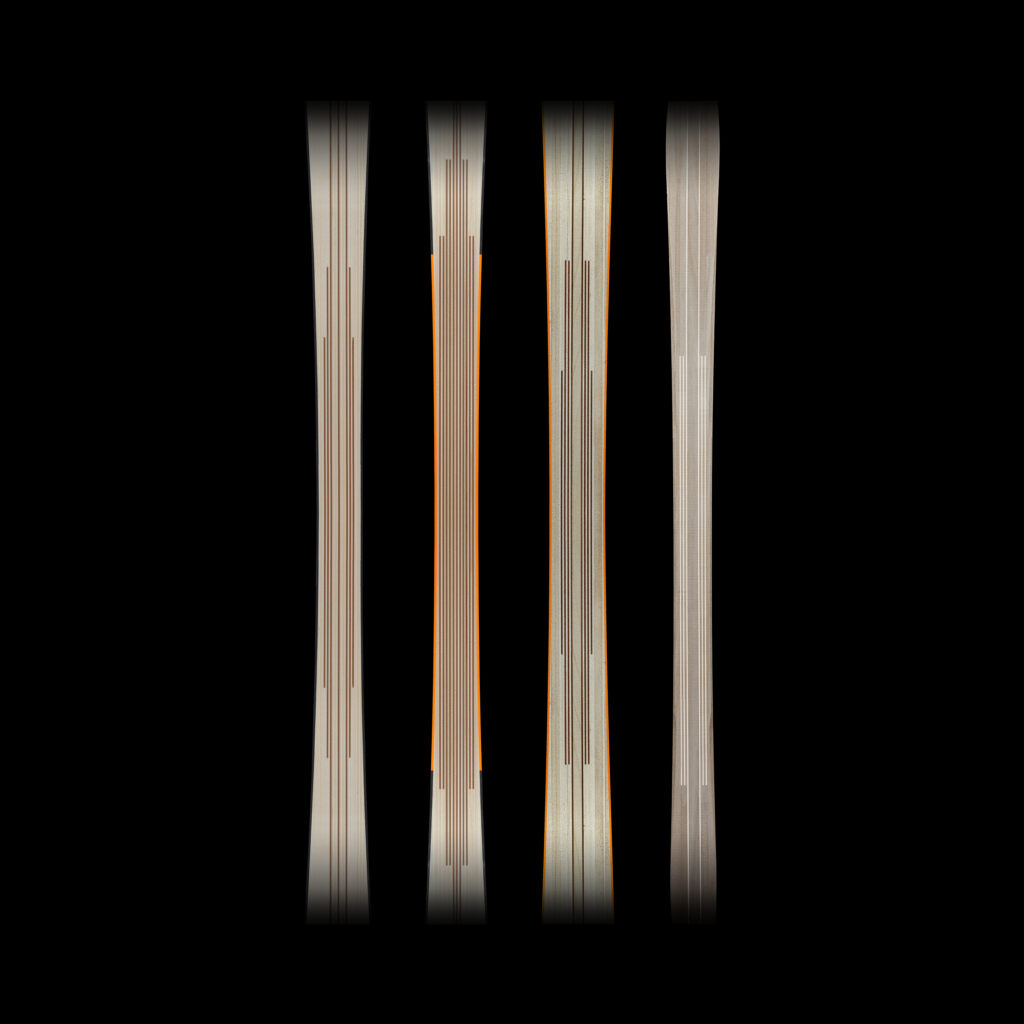

The name of the new ski family says it all: Hustle. Dedicated to those diehard freeskiers, drawn to big mountain terrain, who will do whatever it takes – and skin however far – to get out there and enjoy perfect ski days both on the frontside and backside of resorts. The Hustle series combines our most innovative and light True Bled Wood Core construction with a Carbon D.T.R. (Dynamic Release Technology) in the centre section of the ski, to reduce weight without compromising downhill performance – so that they can access to the backcountry with less effort and still have full confidence when charging.

SN: The Hustle is a unisex collection – do you have any plans to bring any female-specific backcountry-freeride skis to the market?

MP: We conducted an extensive investigation together with our Women 2 Women (W2W) community into whether we needed to build a women’s-specific version of the Hustle and the conclusion was that we did not. As a freeride-backcountry skier, you have a high level of skiing ability. Because of this, we felt that the needs of men and women in this bracket are already embedded in all sizes of the model. For this reason, Hustle will probably be an exception within Blizzard ski collection.

SN: On the subject of the sisterhood of shred, you guys created the W2W programme back in 2015 to connect and collaborate with the global female ski community, build better products and help empower women to take control of their ski experience. How’s it all going seven years on?

MP: The W2W program is stronger than ever. Our products for women – especially the Black Pearl, which has been a best seller for seven years straight – continue to be successful and more importantly are addressing the needs of women with their equipment. We are engaging on many levels with various groups of women within the skiing community with our events, content – which is both inspiring and educational – and our Scholarship Program, which aims to bring more women confidently onto the ski hill and into leadership roles.

SN: When it comes to female role models, they don’t come more inspirational than the late Hilaree Nelson – the world’s greatest ski mountaineer who tragically died on Manaslu on the 26 September 2022. Can you share any personal memories of Hilaree?

MP: Hilaree Nelson was a pioneer. An inspiration and a leader for women in the outdoor world – a force of nature. Her accomplishments are amazing and yet she was so down to earth, so approachable. She constantly worked to encourage other women up in a super-open and positive way. I love this quote of hers: “It’s much easier to be something when you see a path put down by women before you.” And she has laid an incredible path for future generations of women.

SN: As skiers and ski mountaineers, we regularly see first-hand the devastating effects of climate change on the mountain environment. Can you tell us about Blizzard-Tecnica’s approach to sustainability and any significant new efforts in this area?

MP: As father I’m terrified by the destruction of climate change we’ve seen in the last few years. The changes in the eco system are now evident everywhere, from the highest mountain to the deeper ocean, without exclusion. Reducing waist, energy consumption and pollution is a race the entire humanity can’t loose and because of that we all need to do our best.

In 2021, Tecnica launched Recycle Your Boots, with the goal to collect back and recycle old ski boots from any brand and use those regenerated raw materials to create new products, reducing plastic waist, energy consumption and CO2 emissions.

As ski boot makers, we are not just responsible for designing, producing and distributing new ski boots, we also became responsible for the recycling them. The skiers are not just users, they now the power, with a simple action (bringing back their old ski boots to their dealer) to make their sport more sustainable.

Since the first winter season we have collected back and recycled 4,200 old ski boots – a quantity that make us happy and optimistic for the future, especially considering that we have achieved those results with only 54 stores in the seven countries where we launched the project.

By the end of the first three years of the project, we aim to fully recycle 20,000 pairs of ski boots. We are confident that we will reach this quantity thanks to new territories, like the UK, and a growing interest from retailers who are indispensable partners to build an efficient network.

RYB represents our commitment to do our part – and it’s a call to action to the entire ski industry.

SN: Innovation lies at the heart of both brands and we journalists are always raving about technology, such as Trueblend in Blizzard’s skis and T.Drive in Tecnica’s boots. Could you briefly explain the properties of both and why they are so beneficial to skiers?

MP: The Trueblend is a new type of wood core construction that use different blends of woods to perfectly control the flex and the behaviour of the ski. Stringers of harder woods are more numerous in the centre of the ski, below the bindings, where you want to have more support, stability and grip; this is them gradually reduced out towards the tip and tail. Controlling of the length of those harder wood stringers keeps the desired behaviour of the ski the same independently from the length of the ski.

This construction concept is specific for each type of ski; for example a high-performance on-piste ski will have a dedicated blend of types of woods and a higher number of stringers compared with an all-mountain ski, and even more so than a touring skis.

The T-Drive is an engineered carbon connector between the cuff and the shell of the ski boot, which provides two main benefits; firstly, it eliminates undesired deformation and compression of the shell plastic, keeping the same comfort and performance independently from the temperature (softer flex plastics tend to deform under pressure when is warmer and that can create pain points and hinder performance). Secondly, it promotes more efficient transfer of power from the skier to the skis, resulting in more acceleration through the turns with less effort.

SN: You work with some of the best freeriders on the planet in Leo Slemett, Marcus Caston and Elyse Saugstad. How closely do you work with these guys when it comes to developing innovative new products and technologies?

MP: Our athletes are always an important inspiration for us, not only the designers, but the entire team. They redefine the sport and allow us to better understand what skiers want from their gear. We work very closely with them, to understand in which direction we need to evolve our skis and boots, and to also access whether the final products meets their expectation and initial briefing.