Behind the Brand | Fischer

Sophie Nicholson chats to Jan Ekmark - Global Head of Marketing for Fischer - about how the brand has faced fire and war but keeps moving forward

Sophie Nicholson: After 98 years Fischer remains the only family-owned ski company in the industry and one of the biggest ski manufacturers on the planet. What is the secret to brand’s ongoing success?

Jan Ekmark: Yes, we’re the only family-owned ski brand out of the original ones started in the beginning of the last century. I’m not sure if there is a real secret… I believe it has to do both with our success in introducing innovative and high-quality products, and with the passion and dedication to the sport deeply rooted in the company and the family owners.

SN: The last few years have been incredibly difficult for everyone – both as individuals and an industry – but Fischer has been hit particularly hard. Tell us a bit more about the additional challenges the brand has faced recently.

JE: Yes, it’s been a few turbulent years and we’re still in the midst of it. First came Covid, which abruptly put an end to the 2020 winter season, then basically stopped most of alpine skiing in central Europe for the following winter.

In the middle of all this, one night in October, 2020, the news came in that a fire had broken out in our second factory in Mukachevo, Ukraine. Basically, all our ski production there was turned to ashes overnight. At the same time, we had to ramp up production to the max in our factory in Ried. We had to start the project of re-building our Ukraine factory at a record pace to have it ready for a year later. An enormous challenge that our teams took on in an extraordinary way.

But it didn’t end there: just before we were about to resume production, the news broke that Russia had started a war against Ukraine. With more than half our staff located in Ukraine and many of them being recruited for military service, this was devastating. But, just like during the peak of Covid, and after learning that our Ukraine plant burned down, I feel Fischer employees stand united and roll their sleeves up with one clear goal: tackle the issues and get back on track. I believe Fischer can be proud of its many loyal employees in situations like this, but also proud and thankful to our customers and partners for keeping their faith in the brand.

SN: Speaking of challenging situations, climate change is a huge issue for both skiers and the ski industry as a whole. Tell us more about Fischer’s approach to sustainability.

JE: Climate change is a huge issue not only for skiers and the industry, but for everyone on this planet.

Fischer has long worked on finding more efficient ways to produce skis, whether it was the decision to use a circular system for water efficiency decades ago, continuous focus on waste reduction, utilisation of biomass at our Ukraine factory, the partial switch to geothermic energy in Ried, as well as the photovoltaic elements installed in 2019, which produce around 323.000 kWh of electricity per year.

Just before the factory fire in 2020 we kicked off a project with an external consulting firm that will enable us to not only get a benchmark but also measure progress over time, with regard to our environmental impact. We aim to have the report finalised in 2023.

For all new product introductions, our engineers look at possibilities for using more sustainable materials and processes, as long as the performance or durability are not

negatively impacted. Ensuring our products are durable is one of the best things we can do for the environment.

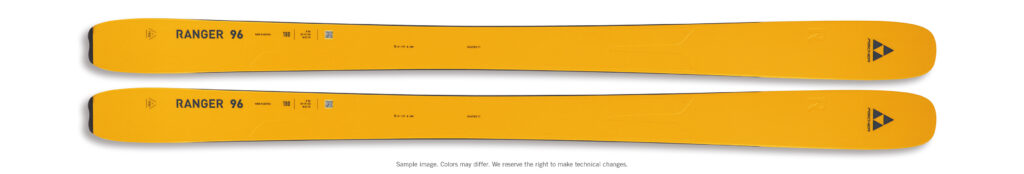

The newly introduced Ranger Ski line is one example where the environmental focus was an integral part of the development process. Each model has 20-25% recycled steel edges. The top sheets are 50% vegetable oil-based and contain 10% recycled materials; the bases are made with at least 50% recycled content. The skis feature a zero-waste wood core and the titanal used contains at least 80% recycled content. Internal calculations show a considerably reduced Co2 impact verses its predecessor model.

SN: One of the most exciting stories for winter 2023 is the launch of the new Ranger series. How did the collection come about and what kind of skier will they work best for?

JE: We started in early winter 2019 by defining the focus for the 22-23 season, which was the new Ranger ski line. The internal product team, our US organisation, plus the Fischer Freeride Team, took a close look at all the relevant competitor products in the segment – on the slopes, in the backcountry, and in the laboratory. They analysed what makes test winners and gained valuable insights. They also analysed the typical consumer for each ski within the line to determine the requirements for each individual Ranger model. They also held workshops with leading retailers in the segment to understand what makes a perfect product for them. Our goal was – and is – to set the benchmark with every model in the collection and to establish Fischer as the top product in the all-mountain/freeride segment, both in the USA and in Europe.

That passionate and dedicated skier is at our core. With the new Ranger ski line we set out to introduce a ski line for a much wider audience though – ranging from intermediate to the best out there.

SN: You have some pretty established talent on your athlete team with the likes of Lynsey Dyer and Kyle Smaine on your freeride ski roster. How closely did you work with your athletes on the design and development of the new Ranger series?

JE: Our athletes are a very important resource for us when it comes to product development. This applies to World Cup products as well as ski touring and freeride.

During the Ranger project we had a core team of athletes specially involved in the development phase from day one until the end. This was Lynsey Dyer, Kyle Smaine, Sandra Lahnsteiner, Max Kroneck, Sabine Schipflinger and Sverre Liliequist. It was a good mix of genders, ages, and nationalities.

There are always preferences from one athlete or another, which we have to consider. On the other hand, we are talking about a collection that includes five different ski widths and constructions. This way we could make sure that the needs and preferences of individual athletes are covered. The ‘go-to’ ski or favourite ski from the collection may differ from athlete to athlete, depending on physical characteristics, where they ski, and their individual skiing style. Nevertheless, the feedback on what works and what can be improved was quite consistent on average during the Ranger project.

SN: Our very own Dave Ryding is another legendary Fischer athlete. Tell us a bit more about your relationship with Dave and how important he is to the brand…

JE: Dave is a fantastic athlete. We say that our passion and dedication to the sport of skiing have enabled us to be independent and successful as a company for almost a century now – and this is something Fischer shares with Dave. Coming from the UK and winning the Kitzbühel Slalom as the first skier from Great Britain at the age of 35 is extraordinary and takes a lot of passion and dedication. Success stories like David’s are something we are proud of and celebrate, and his is just one of our many values athletes helping us as a brand to cut through and gain both visibility and credibility.

SN: Fischer is still the only company offering fully adaptable ski boots thanks to Vacuum Fit technology. As ski boot innovators, can you give us any sneak peeks of what the future of boot fitting might look like?

JE: Thanks to Vacuum Fit technology and the thousands of foot scans we have carried out, we have a unique insight into how consumers’ feet look. This has enabled us to see where we have potential to offer an out-of-the-box initial fit in a standard boot, to be sure that our collection covers more consumer needs than ever before. The Vacuum Fit material and process also offers boot fitters a very easy material to work with to make sure the boot fits perfectly.